Artwork Guidelines

MUST-FOLLOW GUIDELINES

- Submit files in PNG format with at least 150 DPI (300 DPI preferred for best printing quality)

We recommend using PNG for designs with a transparent background. For other designs, we advise preparing files in JPEG instead. - Create files in sRGB colour profile

To ensure your design looks the same when printed as it does on screen, make sure you create your print file in sRGB colour profile. - Use our online mockup designer to determine the size of your design

Our online designer will tell you the exact measurements in CM of your design. You can increase / reduce the size depending on how big you would like it printed. When printed, your design will be printed at the exact measurements you create on the mockup. - How you position your design on your product will be printed in that position

Our online designer is very accurate. Use it to place your design in the exact position you would like it to be printed. We will follow your size & position as best as we can do get your print looking like your mockup.

TIPS FOR BEST RESULTS

- Avoid semi-transparent designs

Semi-transparent graphics (or elements with lowered opacity) don’t translate well in DTF printing. We advise using solid colours if possible. - Create designs with the necessary DPI

Simply typing in a new resolution value into the file won’t result in a higher resolution print. If your graphic’s resolution is too low, the best solution is to recreate it. Our system will automatically determine if your files aren’t up to resolution & point you in the right direction to have it recreated (see here) - Use transparency to your advantage

Black ink will appear grey on black garments because of the white under base used during printing. Leave these areas fully transparent when designing black garments.

NO GARMENT IS PERFECT

Garments are not like other products that are made by machines. Shirts, sweaters, hoodies, etc, are all sewn together by human hands and it’s because of this Human element that variations in the garments may occur.

For example, two shirts of the same size, may actually be cut and sewn differently causing a slight variations in actual size. This also goes for Hoodie pockets and seams. We try to inspect each shirt for obvious variations and/or defects due to the garment’s manufacturing, but sometimes these issues slip through our hands. If you receive any garments that you are not 100% satisfied with due to rips, holes, or inconsistent seams, please let us know and we will work with you to correct the problem.

NEW-SCHOOL PRINTING

We’re moving with the times and taking garment printing to another level with our DTF (direct-to-film) technology. It’s perfect for eCommerce—no setup fees and no minimums.

DTF is the technique we use for most of our garment prints. We use eco-friendly water-based inks that provide unlimited colour combinations and make detailed prints pop.

COLOUR CAN LOOK DIFFERENT IN REAL LIFE

There aren’t many things our incredible DTF process cannot achieve! However, when choosing the colours for your artwork, it’s important to note that they may look different on a real product than what you see on your computer monitor. Even if you have calibrated your monitor to a specific colour profile, there are various factors that influence the final appearance of colours on a printed product. Because of this, we can’t guarantee 100% colour accuracy.

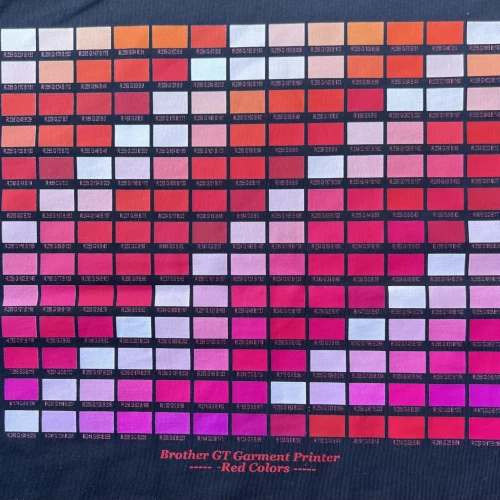

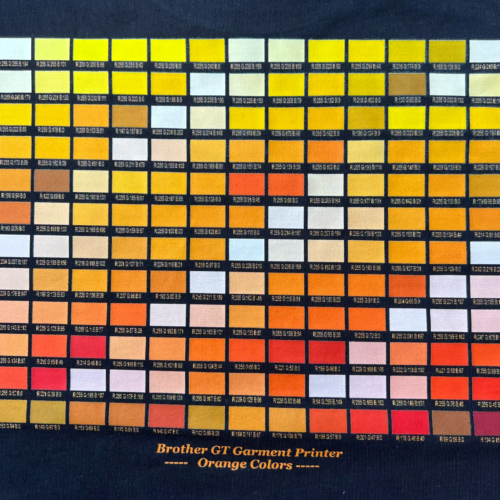

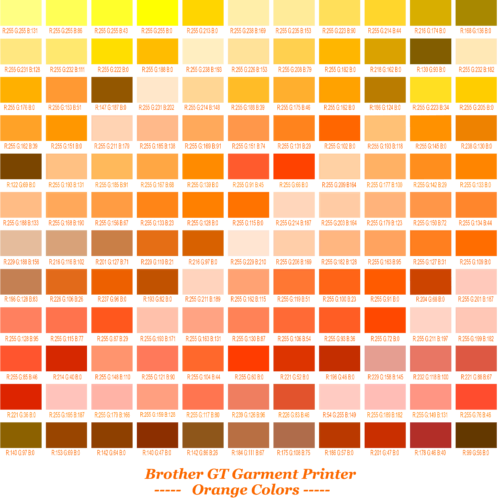

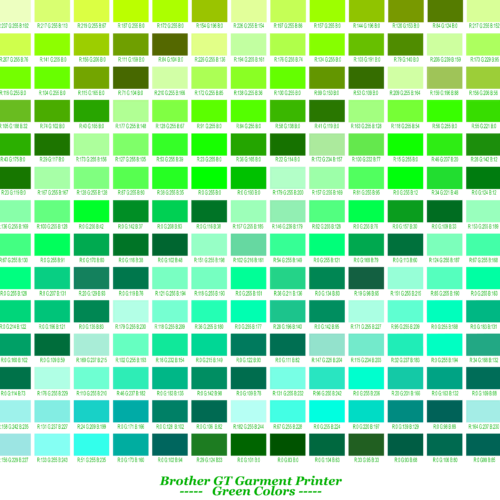

Our printers will convert your submitted print file from RGB to CMYK colour space. This colour conversion process changes the colour gamut or range of colours that can be expressed. You must be very cautious when using bright neon and pastel RGB values in your print files. Some examples include hot pinks, lime greens, construction orange, highlighter yellow, Easter egg shades, etc. You should also consider other factors like fabric material, garment colour, and whether your print will require a white under base layer when choosing colours.

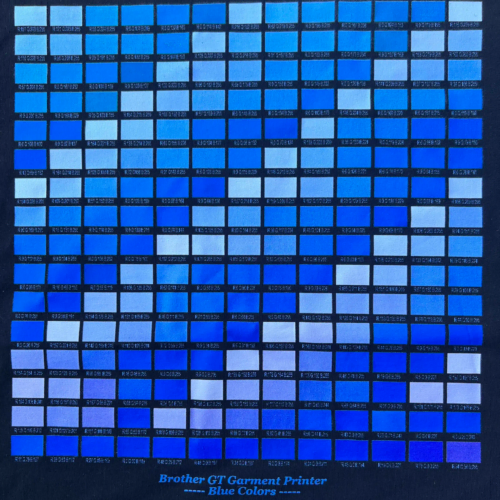

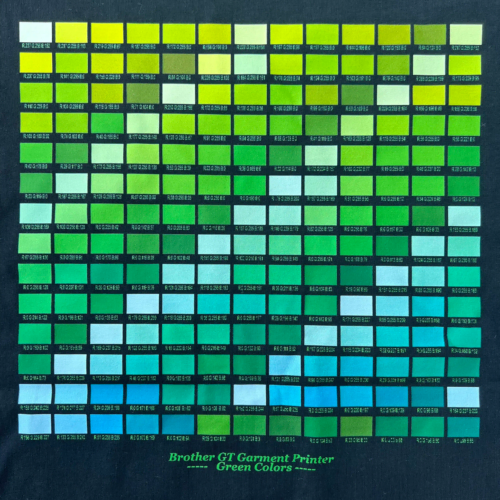

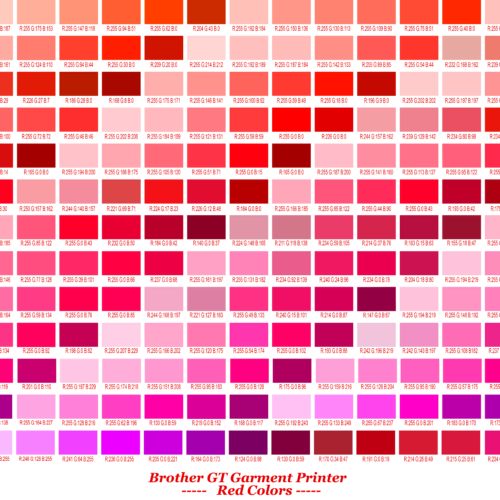

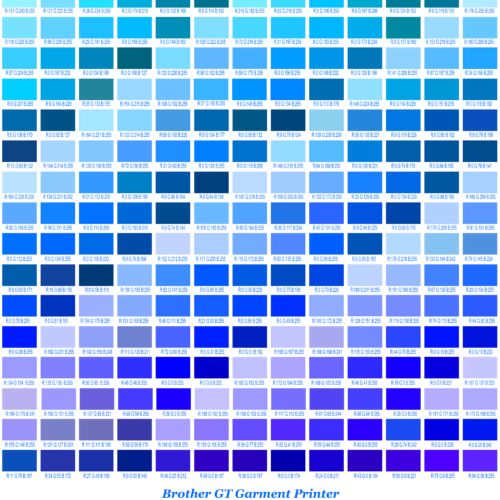

If colour accuracy is important to you, check out our colour matching disclaimer page where you will find images of all specific colour swatches. You can use those swatches to decide which RGB values best compare to the desired results when printed on a physical product. We also recommend exporting your print files in the sRGB colour profile, sRGB IEC61966-2.1 specifically.

DTF DISCLAIMERS

- White ink elements on bright-coloured garments might look tinted. This is most evident on Red, Maroon, and other similarly coloured garments.

- There might be slight discrepancies in print placement.

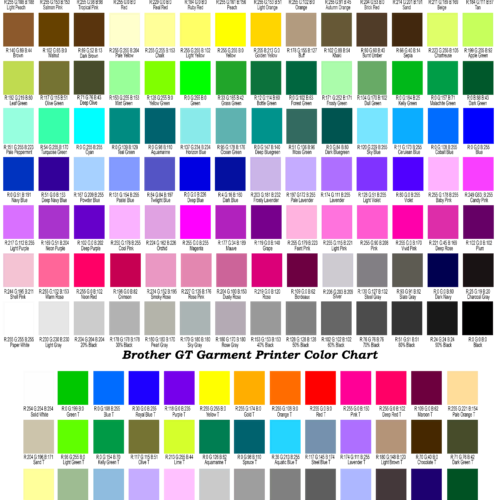

- We can’t guarantee 100% colour accuracy if your files aren’t adjusted using our colour swatches (GTX Colour Pallet).

Colour Matching Disclaimer

If you’ve never had your logo / design printed via DTF before, it basically works in the same way as an office printer. Which means, just like a normal printer, DTF printing is unable to achieve NEON like colours as well as METALLIC colours.

There aren’t many things our incredible DTF process can’t achieve! However, when choosing the colours for your artwork, it’s important to note that they may look different on a real product than what you see on your computer monitor. Even if you have calibrated your monitor to a specific colour profile, there are various factors that influence the final appearance of colours on a printed product.

Because of this, we can’t guarantee colour accuracy 100%. Consider the following factors:

- When printing on garments, it’s important to consider fabric material and garment colour. The same colour value will look a little different on when printed on 100% cotton vs. a fabric blend. Similarly, the same colour value will look different when printed on a light vs. dark coloured garment.

- The two most popular colour spaces are RGB and CMYK. RGB has a wider gamut (the range of colours that can be expressed) and print files made in RGB can be saved as png files. CMYK, on the other hand, is the colour space used when printing. Our printers automatically convert your submitted print files from RGB to CMYK, and this conversion changes the colour gamut. That’s why we suggest you design your file within the CMYK colour space, but convert the file to RGB before saving. For best possible accuracy, convert the file to sRGB colour profile, sRGB IEC61966-2.1 to be exact. This way your colours will stay within the gamut. Most editing programs have this colour profile as default.

- You can download Screenlab’s colour swatches here as well (see below).

We suggest ordering a sample of your logo printed to see exactly how the colours are printed via DTF. Start by selecting a garment from our no minimum range here: https://screenlab.com.au/create

We also have a great Graphic Design Services team if you’d prefer we make any colour corrections for you!

Colour Swatch Files

Join the Growing Community of Satisfied Screenlab Customers

Create Your Custom Tee

Customer Service Hours

Monday: 8:30am – 4:30pm

Tuesday: 8:30am – 4:30pm

Wednesday: 8:30am – 4:30pm

Thursday: 8:30am – 4:30pm

Friday: 8:30am – 4:30pm

Saturday: Closed

Sunday: Closed

Locations We Serve

Operated & printed in 🇦🇺

© 2023 - Taking Custom Tshirt Printing to another level - All rights reserved